These

are intentionally very tight. Using a little grease greatly reduces

the difficulty of fitting these.

In the front and rear of each tread assemble the locking mechanism

(Fig 10).

With the Recanto be careful screwing in the threaded bush as it is

possible to split the tread if this is forced too far in.

The first and last baluster of each tread will pass through 2 treads.

NOTE:

Care should be taken at this stage not to set the grub screw too far

in to avoid scratching the baluster as it is passed through the tread.

Fit

the first and last balusters of each tread, lining up the treads as

you go, Always work from the landing platform down. Do not forget

to add the baluster trim rings as you fit each baluster. The opening

baluster secures into a steel cup which is fixed to the floor (Fig

11).

Next assemble the bush into the underside of the remaining balusters.

Screw these to the treads without tightening too firmly as these will

be adjusted later on. Note at this point that the holes in the tread

for these balusters are formed in the shape of a slot to allow some

adjustment.

For

individual rises (outside 190 - 210mm) it will be necessary to cut

the balusters to length. This can be done by adjusting the baluster

to the centre of the slot then taking A line between the first and

last

baluster on the tread. Any slight inaccuracies can be taken out using

the slot.

Insert the strengthening

pipe inside the handrail. Starting at the top begin to assemble

the handrail to the balusters (Fig.12). Leave

enough spare at the bottom to be able to cut exactly to length afterward.

Check each baluster carefully with a spirit level to ensure it is

vertical in all directions before driving in the screws.

Place the end caps supplied on the ends of the rail to finish it

off.

Brio

For the Brio Carefully position the anti-slip tread mats.

Both systems

As both Brio and Recanto kits are designed to he installed either

clockwise or anti-clockwise it is necessary to drill the landing

platform on the correct side to accept the landing balustrading

supplied. In each kit you will find the relevant template to help

with this.

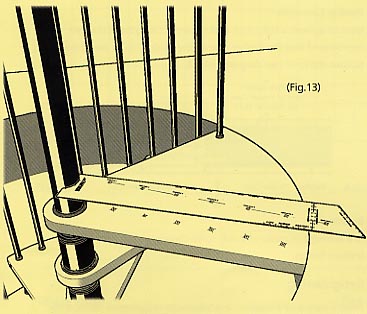

Place the template on the landing platform and drill the holes following the guide. Assemble the platform balustrading (Fig.13).

Adding

strength to your balustrading

A number of optional items are available to increase the rigidity

of the balustrading These should be used wherever possible to ensure

a safe

installation.

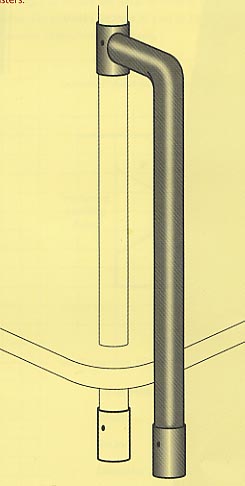

Baluster

to Floor Connector

Can be used on the first baluster of the staircase or on landing balusters.

Baluster

to Wall Connector

Use this to tie a baluster into the apron lining of the well opening

or to finish landing balustrading against a wall.

Greatly increases the rigidity of the batustrading.

Baluster

to Baluster Connector

Can be used where raking balusters pass landing balusters to add strength

to both.

Landing

Balustrading

A number of landing balustrading products are available for you to

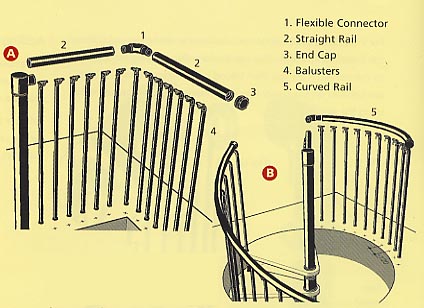

continue the balustrading around your well opening.

Both flexible and straight handrails plus flexible connectors, and

wall connectors are offered. Two examples are provided here which

demonstrate how these components can be used to safely and attractively

guard the stairwell.

Example A

A flexible connector is used to turn the landing platform balustrading

into an L-shaped run of balustrading. At the corner a further flexible

connector is used and finally an end cap and a wall connector are

used to make a firm connection to the wall.

Example B

Is similar to 'A' but shows the use of a curved rail. Again a flexible

connector is used to turn the landing platform

balustrading into the curved run with an end cap and a wall connector

used to complete the installation.

Landing Balustrading Components

End Cap

Used to finish a run of handrail. Where possible should also be

screwed to the wall to provide a stronger run of balustrading. Each

stair has 2 included to start and finish the handrail.

Curved Rail

Available in 6m lengths this rail is capable of being bent to achieve

the required curvature and is used primarily around circular well

openings.

Straight Rail

Identical in appearance to the curved rail this is available in

3m lengths. It is supplied with a timber core to increase the rigidity

of the rail and to maintain a perfectly straight run.

Flexible Connector

Used to achieve a tight turn and to connect lengths of rail. We

recommend that the timber core of the landing rail is pared down

to span the joint (see diagram ).

Retightening

After a period of 2 weeks it is advisable to retighten all baluster

to tread fixings plus the main centre pole nut at the top of the flight.

This will ensure that the staircase remains taut.

Gamia Spiral Staricases